January 3, 2018, our son Griffin married his soulmate, Alexandra Groome.

After the wedding at the Houston Arboretum.

As a wedding gift, Curtis and I gave them one of my early bronze sculptures “lovebirds”.

Bronze lovebirds welded to rebar.

The lovebirds are inspired by my grandparents Imogene Young Travis and Robert Francis Travis, (Granny Gene and Bob-pa). They were married in high school and remained married for 70 plus years. In their El Paso High School yearbook, their senior pictures faced each other and lovebirds were placed in the corners of each of their pictures.

photo of copies of the yearbook pages framed in my house.

The second part of the gift is to make them a faux bois bench for the love birds to sit on.

I am going to make each piece of the bench thinking about the two of them and the lessons I want to pass down from my grandparents and from my own marriage. It will be a reflection of the qualities of the love Griffin and Alex committed to each other that day on January 3rd, and will be a symbol of the characteristics needed to maintain a marriage for a lifetime. My plan is to have it completed by their first anniversary.

Design Considerations:

1. Griffin and Alex are both environmentalists, so I will recycle as much rebar from other projects as possible.

2. No marriage is ever perfectly balanced, so I will make the bench asymmetrical.

3. It will have arm rests for support - symbols of both of their families.

4. When things don’t work out exactly as planned, I will keep an open mind and make the best of the situation. The beauty will be in the imperfections as is life.

5. I will listen to their wedding playlist on Spotify as I work.

6. Griffin and Alex are very playful. The piece will reflect the joy they embrace life with.

I started on Thursday, June 15th. Griffin and Alex are both people-people. They are always reaching out to others and welcoming them into their home and world, they love to entertain. So I decided to make the seat of the bench the shape of open arms.

rebar welded into the shape of open arms that will eventually be the seat.

Next I need to set the seat on jack’s the correct height for comfortable seating. Every couple needs a good support group.

Marriage should be comfortable - The front is slightly higher than the back for comfort.

equality - I use a level to make sure the seat is level from side to side.

Grinding the tip of a piece of rebar cut for a leg.

With small taps I use a sledgehammer to make a gentle curve to a leg.

Next is to creat the armrest and back of the bench.

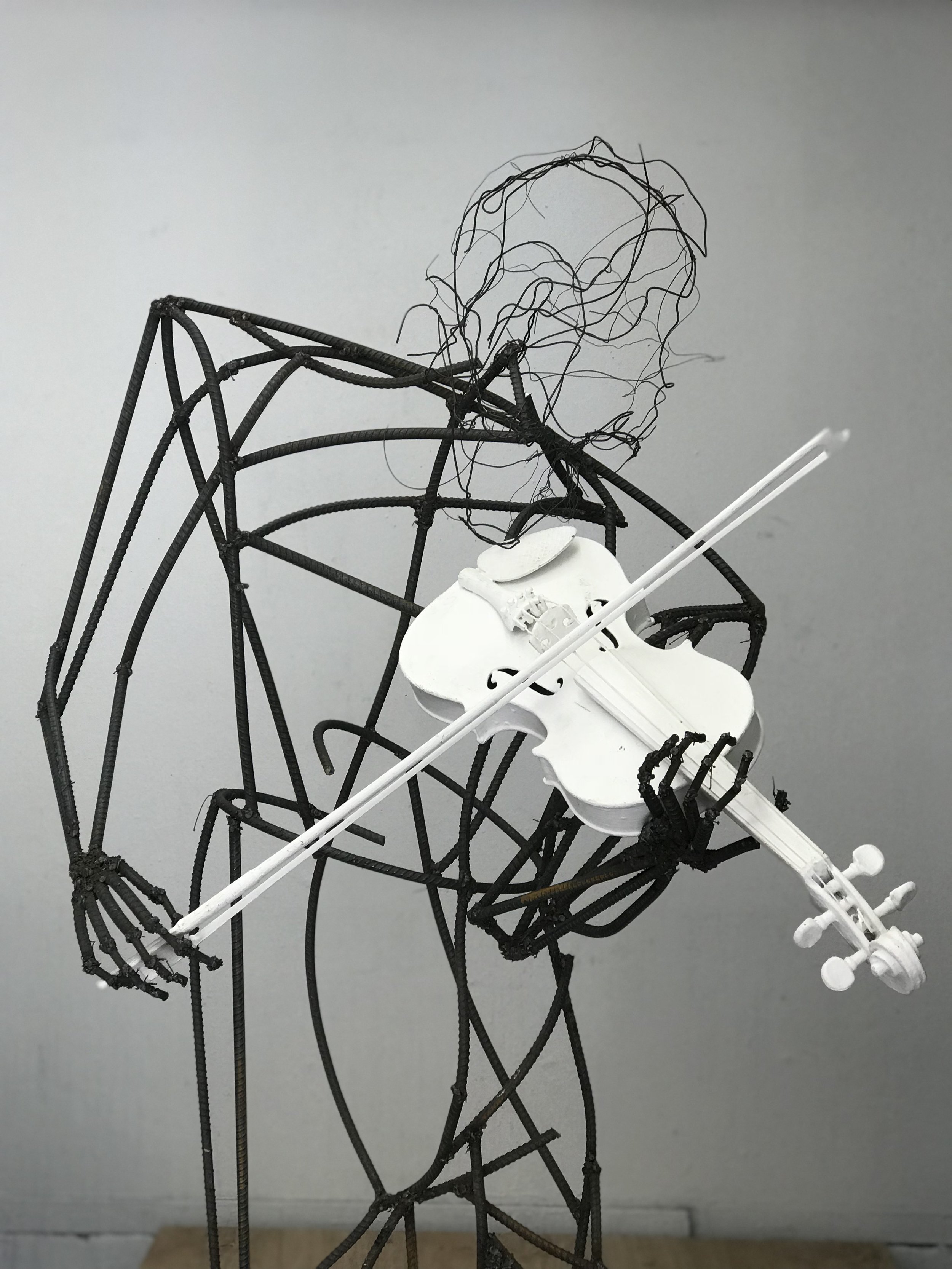

Four legs and two arm rest are welded to the seat.

Griffin and Alex are very fun loving and not inhibited at all to have a good time. The vines/branches that make up the back will embrace this side of them.

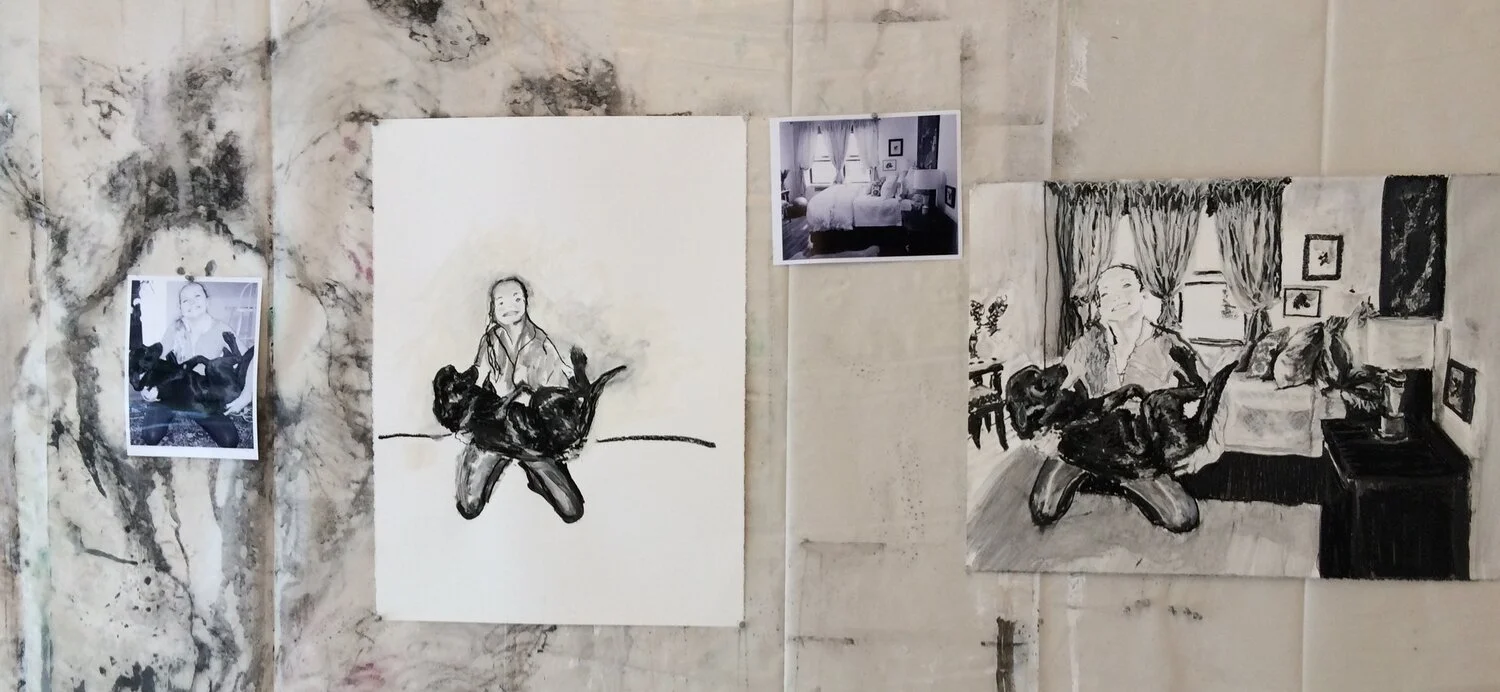

A little sketch of the armature and how it will look with concrete on it so far.

I might need to prune the crazy branch on the left side.