Moving Forward

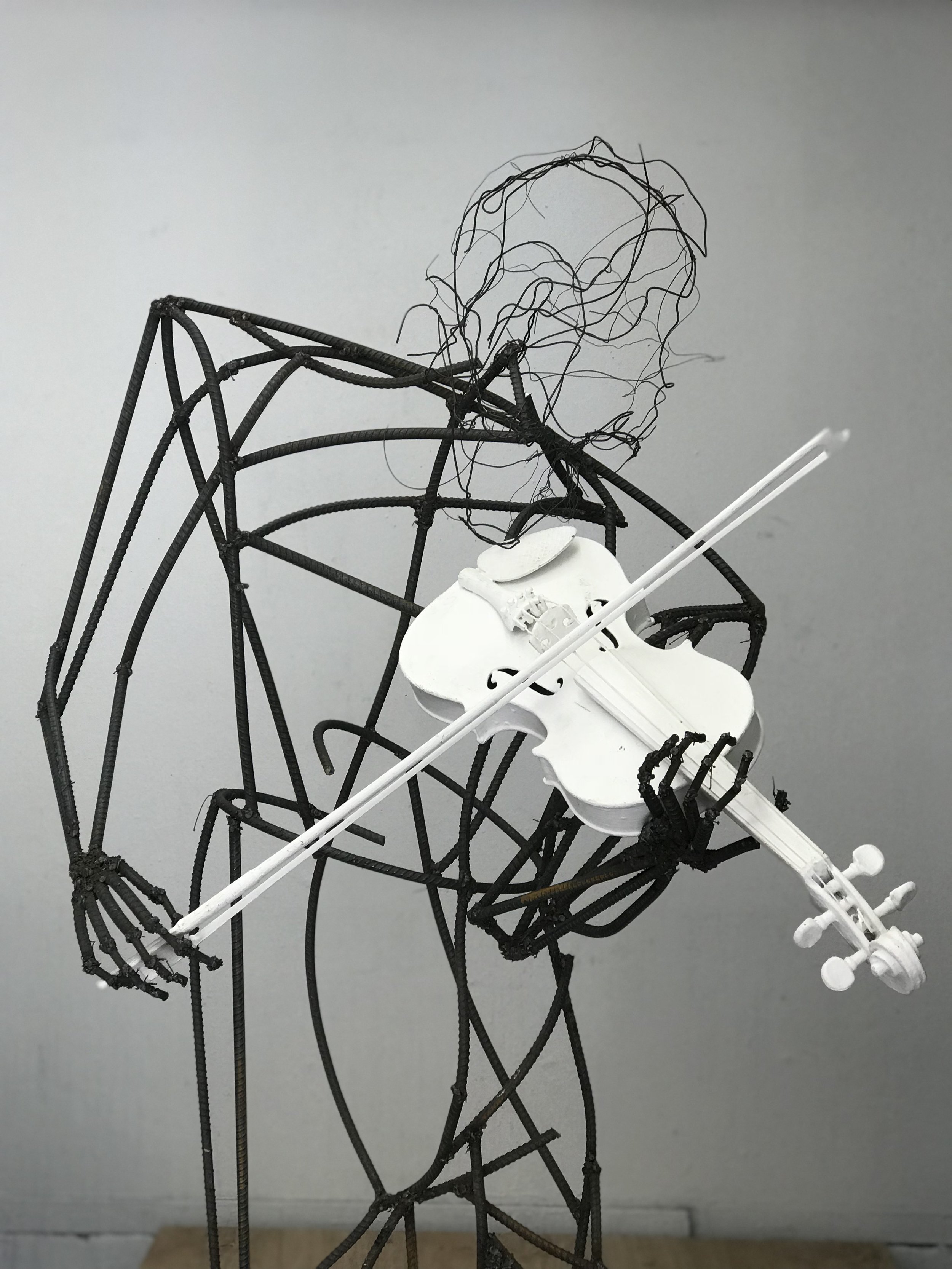

67” X 15” X 18”

Image by Jake Eshelman

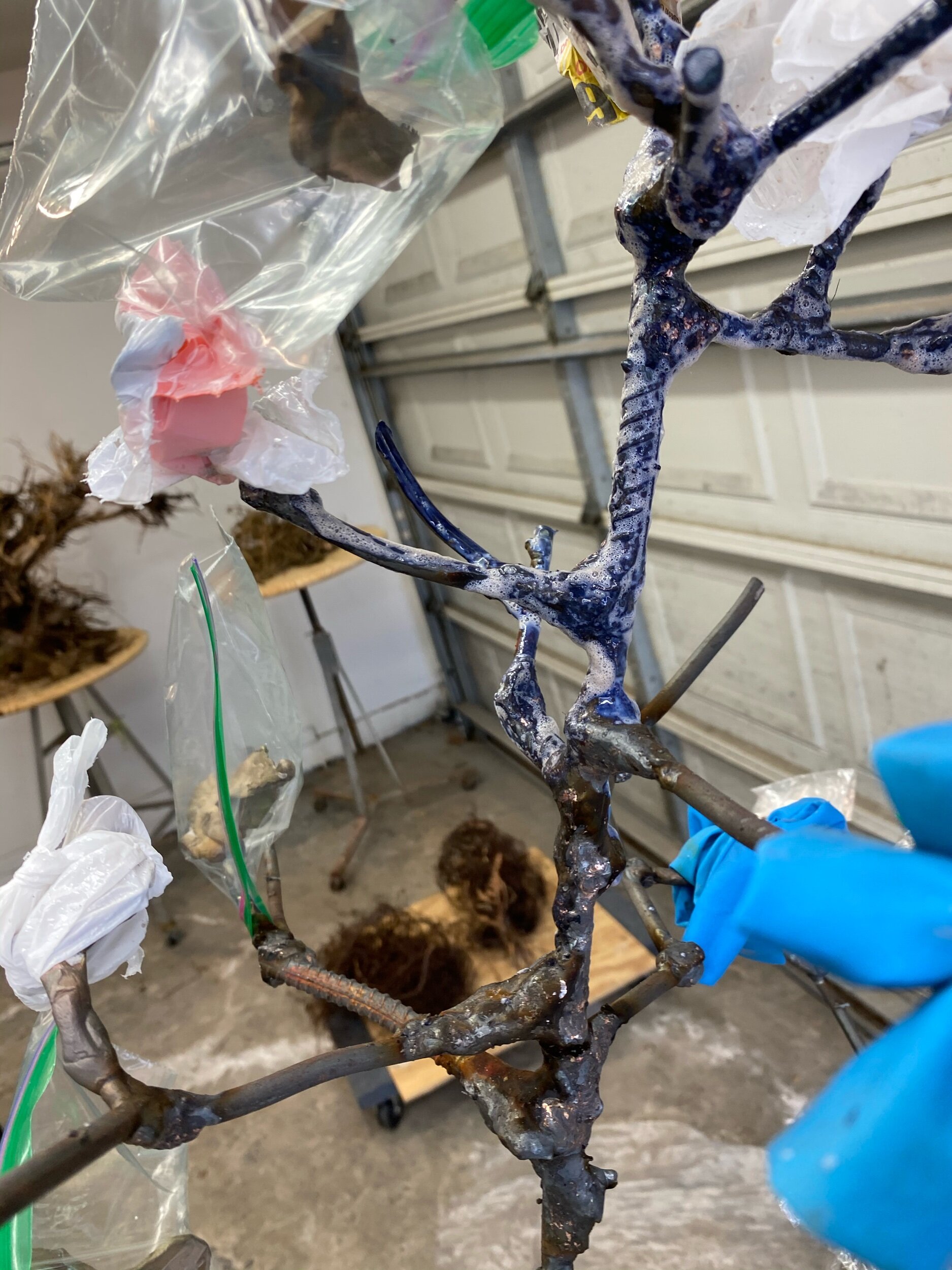

Found object concrete and rebar curbing fragment, rusted steel, bronze, and gold leaf.

Moving Forward consists of two rectangular concrete curb fragments and two cast bronze roots, the latter with gold-leaf patinas. These objects are tethered like irregular beads strung on a wire of rusty rebar falling to the earth.

The fractured concrete and the more extensive root land at the forefront in a forward strutting anthropomorphic structure. Growing behind the long-necked bird-like form, a stem of rebar twice the creature's height reaches for sunlight. The meandering stem is counterbalanced with the smaller root in a lyrical passed sunflower shape.

The weighted composition invites viewers to reimagine the relationship between our engineered landscapes and ecological systems to support wildlife and forge a path toward a regenerative future.